Awards are a way to appreciate and celebrate someone’s achievements. They can come in many different shapes and sizes and be engraved with a variety of designs and messages.

Perhaps you’ve never given much thought to the different types of engraving for trophies before but the type of engraving you choose will affect the material you can use and the look you’re going for.

In this blog post, we’ll explore the different ways awards can be engraved and why each method might be chosen. So, whether you’re looking to buy an award or have your corporate recognition awards engraved, read on!

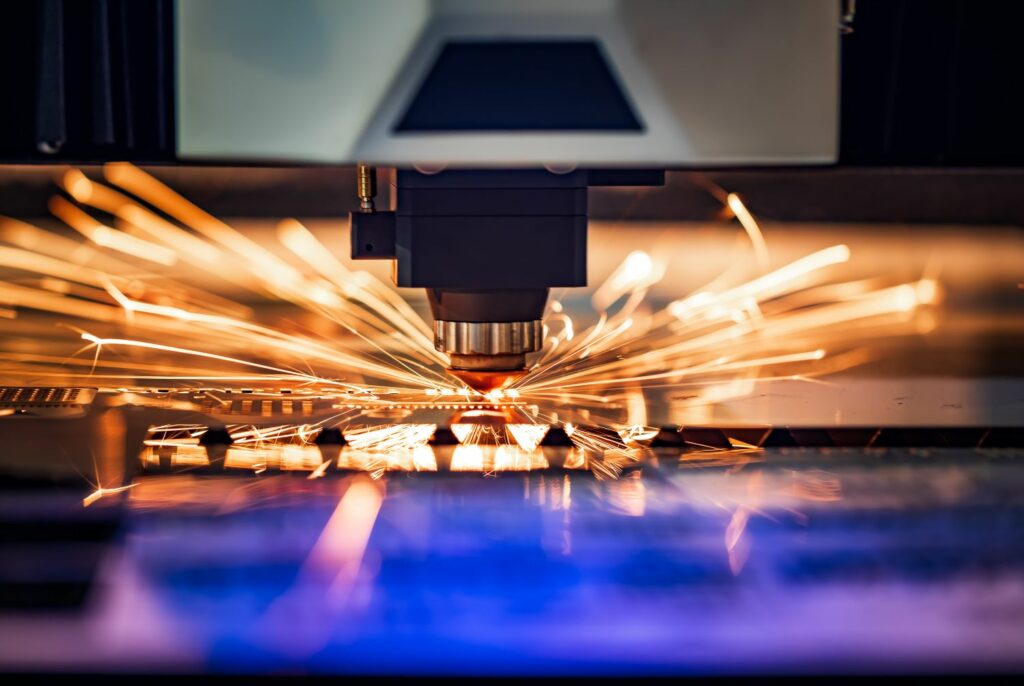

Laser Engraving

This is a popular choice for trophies because it is very precise and can be done quickly. Because of this, it’s often the most affordable option. A laser beam is used to etch the design into the trophy material. It can only be done on flat surfaces, such as the plates on the bases of trophies.

Abrasive Etching

Also called deep etching, this is the most detailed type of trophy engraving. It’s a relatively in-depth process that involves creating a template and using a sandblasting technique to etch the design. This is the type of etching used on our crystal awards and trophies.

UV Printing

UV printing is a method of producing photographs and text with high clarity using quick-drying inks that are then UV light cured. This gives text and images sharper detail.

Full color

When we say, ‘color fill’, this is referring to the process of adding color to cut lettering, logos, or designs. This is often necessary for contrast on metal plates, a common type of trophy engraving. Most commonly, you will see this used in black, gold, and silver although other colors can be chosen too.

Sublimation

In sublimation, rather than engraving the trophy, we imprint it. Using specialized machinery, high pressure and heat are applied to transfer letters or images onto the custom award in vivid, long-lasting colors. Sublimation printing is often preferred over engraving, as there are endless color options and design possibilities.

Sandblasting

The process of sandblasting entails finely engraving the text, logos, and graphics onto crystal, glass, acrylic, and metal. It may be more costly than other methods, but it guarantees a stunning frosted look.

Screen Printing

Screen printing is commonly used on plastic trophies as it is a very affordable option. In screen printing, the design is transferred onto the trophy through a mesh screen. This type of engraving is not as precise as laser or traditional engraving, but it can be done quickly and is very budget friendly.

Now that you know the different types of trophy engraving, you can make an informed decision about which type is right for your next custom company award. No matter what type of trophy engraving you choose, Awards & Engravings in Baytown, Texas is here to help! We offer all types of personalization and engraving services to meet your needs and budget. Call us today or stop by our shop to get started on your next engraved award or trophy!